ABOUT DSPC

RELIABILITY AND FLEXIBILITY FIRST

DSPC was founded in 1923 as the De Sweemer Foundry and for more than 90 years has been active as a producer of castings in lamellar, nodular and alloyed cast iron weighing anywhere between 0.1 kg and 6.5 tonnes.

Our foundry staff have many years of experience producing castings for our wide range of clients in Europe and beyond.

Following our recent expansion DSPC is now fully equipped to produce bronze castings for the glass moulding industry, and we are currently one of the fastest growing players in this sector.

Not many foundries have the capacity and equipment to produce both ferrous and bronze castings as offered by DSPC. Our metallurgical staff perform an in‐house analysis of all the casting operations, thus ensuring that DPCS produces your castings according to your material specifications. The entire process is carried out at our site, from the initial CAD drawing and model designing up to the processed final piece. This allows us to offer you very short and low‐cost throughput time.

Our core values – including reliability and a relentless ‘customer is king’ attitude – ensure that our clients receive full backup and support.

We guarantee short response times to comply with strict delivery schedules or to produce nonstandard pieces.

EXPORT

Our industrial casting clients are in Europe and beyond. Orders for castings for the glass moulding industry mainly reach us from European countries such as Portugal, France, Spain, the UK, Germany, Poland, Hungary, Italy, Croatia… and more. Supreme technical knowledge and top‐quality products enable us to cater for a wide market and to supply any required type of glass mould.

Centrally located and well‐connected to various types of transporting companies, DSPC offers efficient and economical distribution of all your products to every country in Europe and the rest of the world.

BRIEF HISTORY

START‐UP OF THE FOUNDRY

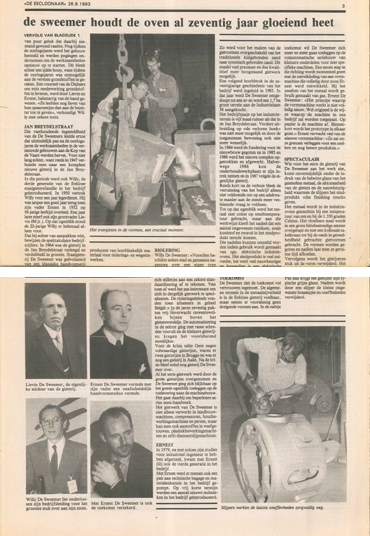

Lievin and Ernest start the foundry at Kop van de Vaart in Eeklo.

MOVE

The company moves to a new foundry in the Jan Breydelstraat. Willy, the third generation of the Eeklo foundry family, joins the company.

UNDER WILLY’S MANAGEMENT

After Ernest and Lievin’s passing, Willy is on his own.

GROWTH

By 1964 the foundry has doubled in size. It now develops from manual casting to semi‐automated production of pieces for sewerage and road works.

EXPANSION

Ernest (II) marks the entry of the 4th generation into the company. Introduction of new technology.

MOVE

The company moves to a new complex at Industrielaan. Introduction of electric induction furnaces for a purer and more accurate product.

BRONZE

Expansion to include casting for the glass moulding industry.

NEW FOUNDRY

Commissioning of the new foundry including Omega moulding line.